Vinçotte and SkyeBase : An integrated approach for your tank inspections

Vinçotte – Expertise & Advanced Inspection Techniques #

We combine state-of-the-art technologies with in-depth expertise in inspection standards such as ASME, API, EN, ISO, and EEMUA. Our qualified inspectors ensure that all your assets remain compliant with these standards and legislation.

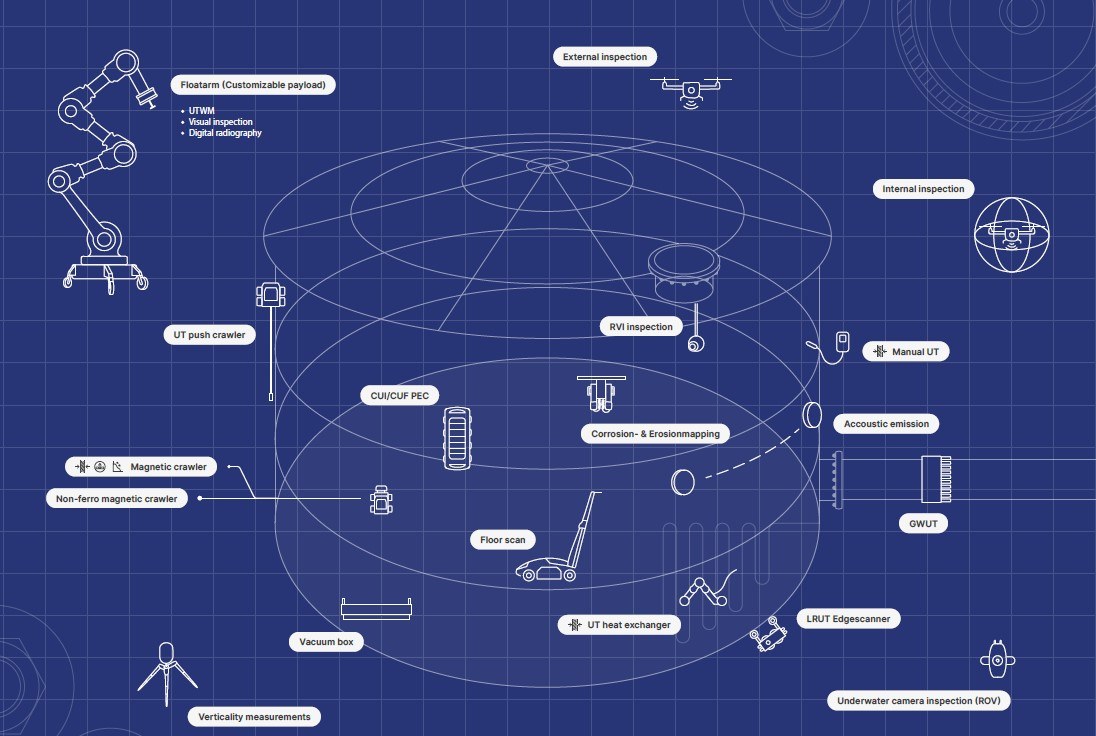

Remote Visual Inspection (RVI) forms an essential part of the broader Non-Destructive Testing (NDT) inspection process and works complementary to Ultrasonic Testing (UT), Phased Array (PAUT), Radiography (RT), Crawlers (Ferrous and Non-Ferrous), MFL Floorscan, and other methods. While RVI assists with the initial detection and localization of defects, these advanced techniques provide deeper analyses and validation.

SkyeBase – Remote Visual Inspection (RVI) Partner #

For Remote Visual Inspection (RVI), we collaborate with SkyeBase, our specialized partner in drone inspections and digital image processing. RVI plays a crucial role in the inspection process by quickly detecting surface defects, corrosion, and other anomalies.

Thanks to advanced technologies, SkyeBase offers safe and efficient inspections, resulting in detailed analyses and accurate trend monitoring.

RVI is an essential part of the broader tank inspection process. #

While RVI assists in the initial detection and localisation of defects, UT measurements with drones can be carried out safely and efficiently in hard-to-reach or high locations, enabling rapid and reliable assessment of damage or corrosion.

This technique complements other advanced NDT techniques.

Advanced techniques such as MFL floor scanning, PA Edge scanning, Crawler (ferrous and non-ferrous) and other methods then provide in-depth analysis and validation of the defects identified.

Download the flyer

Find out more about our full range of tank inspection solutionsBenefits of an Integrated Inspection Approach (RVI + NDT) #

✅ Faster and More Targeted Inspections

RVI serves as a first screening, allowing inspectors to directly identify critical zones and apply more targeted NDT techniques (UT, PAUT, RT).

✅ Higher Reliability & Completeness

By combining RVI with NDT techniques, both surface and internal defects are detected, leading to a complete and accurate inspection result.

✅ Cost Savings & Increased Efficiency

By deploying specialized NDT techniques only where necessary, we reduce unnecessary examinations and save costs without sacrificing quality.

✅ Improved Safety & Risk Management

RVI eliminates the need for physical access to hazardous or hard-to-reach locations, significantly increasing inspector safety.

✅ Data-Driven Insights & Trend Analysis

Digital inspection results enable longitudinal analyses and predictive maintenance, allowing companies to address defects in a timely manner and minimize downtime.

✅ Full Compliance with International Standards

Our inspections comply with the strictest international standards (ASME, API, EN, ISO, EEMUA) and are performed by certified experts.

UT application with drones for tank and site inspections #

UT application of drones makes it possible to inspect tank walls and roofs, both fixed and floating, more quickly and frequently.

Thanks to digital images and videos combined with UT measurements, information can be easily stored, shared and analysed.

This helps to detect problems such as corrosion, leaks or structural abnormalities at an early stage.

Advantages #

✅ Safety

Avoids working at height or in hard-to-reach areas.

✅ Efficiency

Inspections can be carried out faster than with conventional methods.

✅ Accessibility

Possible in places where human access is limited or dangerous.

✅ Consistent results

Drones can follow programmed routes for repeatable and uniform measurements.

✅ Early detection

Problems such as corrosion or wall thickness reduction can be identified more quickly.

✅ Cost-effective

Reduces the need for scaffolding, hoisting equipment or operational downtime.

✅ Licenced

We take care of everything for you by arranging all the necessary drone licences for outdoor flights, based on our official certification.